Data Center Construction At Warp Speed: Santa Clara’s CoreSite

The CoreSite SV7 data center in Santa Clara, CA went up in record time.

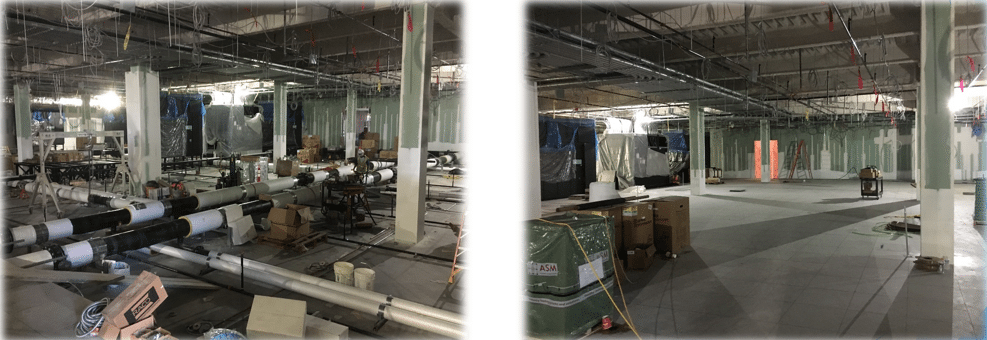

MATT Construction knew going in that the fourth project for CoreSite would have a condensed schedule, but even our veteran team members were astonished by the breakneck speed of the highly technical Santa Clara project.

“All in, we put about $200M of construction in place in 10 months – demolition to TCO.” – Project Executive Mike Fedorchek

Fast Out of the Gate

CoreSite’s goal for the four-story data center and interior bulild was speed in construction. To deliver, MATT Construction used ConXtech for the structural steel. This allowed installation of 240,000 sf in 25 days, and was 25% faster than a traditional structural steel installation.

A local Bay Area product, ConXtech is a four-way, self-truing, moment-connecting structure. The rigid connection of the beam and post at the frame can take rotational force, eliminating the requirement for heavier steel to meet seismic needs. The system eliminates the need for field splicing and on-site welding, and is ideal for SV7’s grid structure. In addition, no braces or shear walls are necessary, which means ultimate flexibility on the floor plan – a plus for data centers. As MATT has prior experience with the system, the team had the advantage of understanding ConXtech’s intricacies and requirements and so could achieve full installation efficiency.

From that rapid start, work at CoreSite continued at a clip. The project ran three shifts, and the team averaged 400 people on site during the day and 50 at night.

Moving to Warp Speed

Thanks to a positive community reputation and deep relationships with local subs, MATT was able to deliver a high level of quality for CoreSite at a feverish pace. Below are a few examples of work that was accomplished in one two-week period:

All exterior terracotta rain sheeting, framing and Tyvek completed.

Two-week catwalk evolution: from steel and mini beams to installation of two 18″ condensed water pipes welded together, steel structure supports, catwalk grading, upper steel and 5,000-pound filter boxes for the generators.

In the data room, MATT coordinated support pedestals and seismic backing, electrical conduit, fire sprinklers and alarm, and the installation of the three-foot-high raised floor.

In two weeks, the chiller room, which was needed to provide AC to the second floor so the owner could move in early, saw all piping run to the data room and the first-floor thermal storage tank, which was housed outside underground.

On the roof, AC and water coolant equipment to serve non-data spaces, including two cooling towers, were installed, and a 600-ton crane brought in the air handlers.

The team kept the project on schedule via close collaboration and early communication with the subcontractors, so that MATT’s superintendent could appropriately and efficiently coordinate the work and keep all teams productive simultaneously.

Getting the Best from the Team

On a tightly scheduled project, one is bound to encounter schedule overlaps and coordination challenges between trades. Meeting these challenges with the big picture in mind helped the team to stay on, and in some cases, improve the project schedule. In one example, a delivery of very heavy electrical equipment to be installed on the third floor was arriving at the same time that the raised floor was scheduled to go in. As moving the equipment across a raised floor would have been difficult to rig, the floor installation was paused for a few days so that the equipment could come in on a forklift and the electrician wouldn’t have to come back later. Though the raised floor installation was interrupted for two days, the schedule gained a week on the power distribution unit install, for a net gain of three days.

What is the key to navigating the inevitable conflicts between trades and keeping everyone working together, even when it delays a specific subcontractor’s work? It comes down to trust.

“Our subs know that if they have to sacrifice a bit of efficiency in one area for the sake of the project, they’ll get taken care of by us in the end,” says VP and Senior Project Manager Greg Wade. “We’ll make it up to them in time by scheduling them first somewhere else.”