MATT Construction Celebrates Monumental Topping Out at The (W)rapper

Final steel beam is raised to the top of LA’s first exoskeleton building

A Ceremonial Event

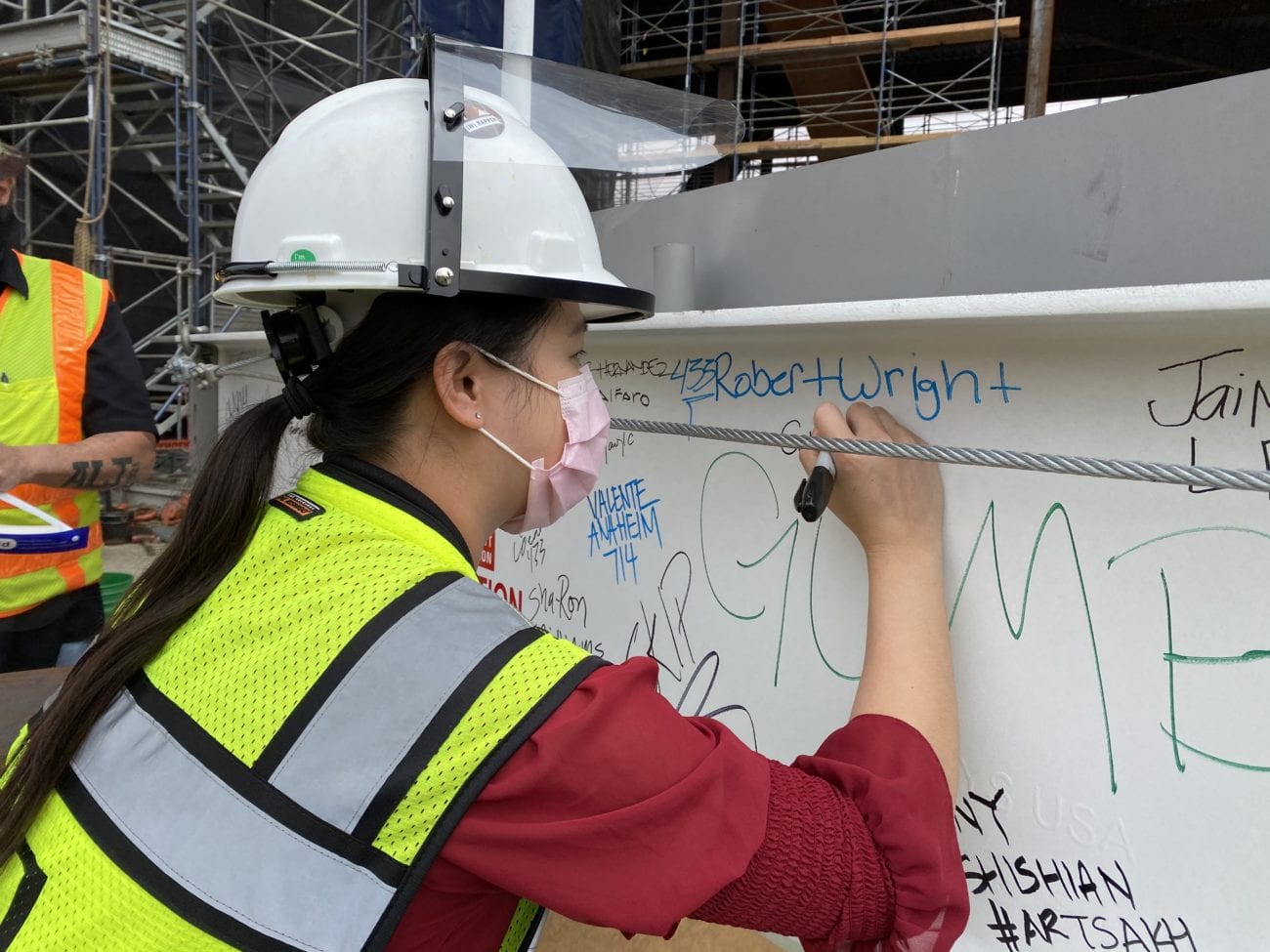

Earlier this month, the team at MATT Construction celebrated a major milestone at the (W)rapper, LA’s first exoskeleton building. In stride with the topping out tradition, an evergreen tree, American flag and SME Steel flag were placed atop the building’s final steel beam as it was erected upon the top of the cutting-edge tower. Over 250 construction workers, architects, engineers, and developers joined together to autograph the beam, observe the installation and celebrate this monumental event with a barbeque lunch.

A One-of-a-Kind Venture

Over two decades in the making, the daring concept for the (W)rapper came to life through the design of Eric Owen Moss Architects. Traditionally, a building relies on columns and beam framing to structurally support itself. What makes the architectural intention behind the (W)rapper groundbreaking is the method to support from the outside-in, rather than the inside-out. After years of engineers and architects calculating the possibilities, the method was conceived where eight steel bands abstractly wrap around the building and connect to isolator nodes which sit on base isolation, which in turn rest atop concrete pilasters. These outer steel framing bands, also known as the tower’s exoskeleton, serve as external columns. Because of the unusual design, the steel spines were milled in Germany, shipped to China for fabrication along with the rest of the bands, and then sent to Los Angeles to be erected. Although its roots are planted in Los Angeles, the (W)rapper has been made possible by a collaboration of global efforts that make this building truly incomparable.

“What is uniquely rewarding about this project is that we are building something that is truly one-of-a kind. As a team, we have to piece things together with a collaborative drive to work with what is presented to us in each moment,” says MATT Project Manager, Cory Kuo.

A Milestone Unlike Any Other

SME Steel, one of the largest fabricators and erectors of steel in the United States, ensured the safe and high-quality execution of the steel band placement throughout the process of this project. After a year of much uncertainty due to the COVID-19 pandemic, the topping out of this project was an exciting and rewarding moment to say the least. “Although there is still plenty of work to be tackled, watching the final beam go up on this tower truly does memorialize the moment. The amount of people, hard work, and perseverance that has gone into the (W)rapper already is truly astonishing,” says Scott Fitzsimmons, Project Manager at MATT.

Having broken ground on the (W)rapper in late 2018, the project team executed a large majority of this project’s steel erection under COVID-19 restrictions. The team’s unceasing determination to overcome the many obstacles presented by COVID-19, ensured their ability to make progress with the construction.

What’s next for the team at the (W)rapper? After the exoskeleton is completely welded, it will be cut free from its temporary shoring frame, leaving the building to support itself. The de-shoring will be the next big milestone that brings the team one huge step closer to completing this revolutionary building.