Photo credit: Tom Bonner

Location

Pasadena, CA

Owner

California Institute of Technology

Architect

ZGF

Project Size

95,000 SF

ViewCO Architects and MATT Construction Collaborate on Design-Build Labs for Caltech

CO Principal, Andrew Labov, Reflects on Building Custom Design-Build Labs with MATT

Scientific vision thrives on collaboration and environment. The right group of researchers, working together in a laboratory tailored to their specific agenda, can yield major breakthroughs with far-reaching impact. But how do you construct and configure an ideal research space, one with the right conditions for such breakthroughs to occur?

One of the most exciting elements of the design-build approach to construction is the fluid exchange of ideas it engenders. The design itself evolves as part of a dynamic dialogue amongst several key parties, including end-users, architects, contractors and engineers. With a general contractor on hand from the outset, any potential constructability or budgetary issues can be identified and addressed early enough to brainstorm creative alternatives that still incorporate the original intended function of the element in question. Naturally, this makes design-build an ideal model for bringing cutting-edge laboratory spaces to life.

The California Institute of Technology (Caltech) has partnered with CO Architects and MATT Construction on a series of bespoke laboratories to suit the current and future needs of leading researchers in their fields and to accommodate the ethos of learning, teaching and sharing that is central to Caltech’s mission. In conversation with CO Architects’ Science and Technology Director, Andrew Labov, we’re taking a closer look at the design-build process for two recently completed labs.

Labov came into these projects with over three decades of experience in the research laboratory and undergraduate academic sciences sectors. He knows how to take a blank canvas and tailor it to the precise needs of numerous sub-disciplines. MATT, in turn, has built a wide range of academic research laboratories and understands what such spaces demand from a constructability standpoint.

Alongside MATT Construction’s team and Caltech’s scientists and facilities managers, Labov developed the Space Solar Power Initiative (SSPI) and the Center for Autonomous Systems and Technologies (CAST), as well as a series of other bespoke labs across different departments at the institution. SSPI and CAST are both located in the Cold War-era Karman Laboratory Building. Professor Sergio Pellegrino leads SSPI’s efforts to design space-based solar energy initiatives that could have major power ramifications on Earth. CAST, helmed by Professor Morteza Gharib, tests drones that may be used for planetary exploration, emergency disaster response, aerial deliveries, mobility enhancement and more.

Working with the Space

What you have to work with plays a huge role in determining any lab’s potential capacity. Repurposing an existing space comes with its own challenges and opportunities. Both the SSPI and CAST teams had chosen the outdated, post-WWII Karman Building to house their new laboratories.

When Caltech approached Labov for SSPI, the project was open-ended. “Normally they do fairly detailed drawings of labs showing the locations of all the equipment they want,” he recalls. In this case, however, the team would be working with a two-story basement full of giant water flumes that had once been used to test the shape of torpedoes and submarines during the Cold War. Other relics from the era sat atop a two-story-high base and platform in the center of the space, making it difficult to visualize potential. The team demolished everything and cleaned the space out. MATT’s crews have dealt with tricky as-builts throughout many restoration and adaptive reuse projects in the past, so encountering them in the Karman Building was both expected and navigable. Once they had cleared the space, layout possibilities began to take shape. Labov comments that “if we were trying to do a project like that without having the contractor on board from the very beginning, it would have been more difficult to figure out. Having MATT on board for constructability and cost was key.”

Smoothly maneuvering materials into the space proved its own daunting task. Although a service elevator from a bygone era already furnished the basement, it was too cramped to transfer all necessary construction components into the space. Leveraging the benefits of a design-build approach, MATT’s team weighed in on the most feasible options. Troubleshooting tight constraints is a frequent job requirement in congested urban construction, making MATT’s crew well-versed in coming up with creative fixes for similar access issues. Discussions and reviews of the problem led to a number of successful workarounds, such as fishing steel beams through tiny clerestory windows with a hoist.

While the team was still working on SSPI, Caltech approached CO and Labov for a conceptual rendering of the space above them, part of which would involve turning an open-air courtyard into a semi-outdoor testing arena for drones. The architect quickly realized that their entire SSPI team would need to pivot in their approach to the SSPI design: “We needed to start thinking about utilities and what decisions to make on the SSPI project that would keep us out of trouble once we were working one floor above.”

They would need to rethink some of the locations and proportions for ductwork, especially because the 1940s building featured no central shaft. That meant routing ductwork up the side and exterior of the building along the same courtyard they could soon be converting into a robotic staging zone. They had to factor in ways to minimize impact on the future use of the space without fully yet knowing what the space would feature, so they opted to rerun power and piping in such a way as to leave themselves as free and unencumbered as possible. Luckily, having MATT’s team present to weigh in on the best options and coordinate the work enabled the designers and crew to pivot without missing a step.

End-User Benefit and Collaboration

Coordinating and cooperating with the people who would be using these spaces day in and day out proved crucial to getting the design right. Labov emphasizes the importance of first establishing a universal language. He urged Caltech’s team to “explain this to me like I have to explain it to my mother.“ Comprehending their work at a basic level and building from their perspective enhanced CO and MATT’s ability to supply the right vision. Caltech encourages this fruitful flow of ideas. At one point, a Caltech student even ran a mock presentation of his thesis defense for an autonomous systems project while the design team listened attentively, pints in hand. The organic feedback that emerged from this impromptu, casual session helped the student to craft his talk and deepened the designers’ grasp of the type of work they were creating space for in the future.

Labov goes on to explain the impact of clear communication and its rewards: “Being able to have some part in designing architecture around science, working with engineers and scientists whose own work is developing, meshing our design work to that, we feel like we’re part of the scientific process. We’re not scientists, but what they’re doing is evolving in such a way that we have to get very involved and understand what they do at a level we don’t normally have to on other projects.” If you don’t understand what their vision is, your vision can’t serve it.

MATT and CO’s teams met with professors, lab technicians, graduate students and facilities representatives to begin initial programming. They implemented an interactive exercise to categorize perceived needs: “We identified all the different spaces and their attributes, the characteristics that these labs should have, then ranked them as far as ‘must have,’ ‘should have,’ and ‘nice to have,’” Labov shares. “We wrote them on Post-It notes and had them rank them on their own and contribute to a highly democratic process. We came to a consensus over priorities, which proved helpful for budget and space constraints.” In the rare instance of a conflict, the facilities group worked with everyone to find a suitable alternative solution. For more marginal requests, the team tried to either provide utilities for future use or find a different way to accommodate them.

Overcoming Construction Challenges and Firsts

Without an actual layout in mind yet for SSPI’s cavernous two-story space, CO and MATT worked with user groups from Caltech to define their needs and translate them from the abstract into the concrete. Labov and MATT encouraged the scientists to take the rectangular shape of the space as a given parameter and then figure out how best to arrange themselves within that space, accounting for several very different kinds of lab spaces and equipment, such as an electronics clean room and a chemical vapor deposition device. Professor Pellegrino and his team were developing thin solar sails that would unfurl in outer space to harvest solar energy and potentially send it back to Earth. Labov remembers with a laugh, “The irony of building solar panels in a basement with no natural daylight was not lost on anybody!” Despite the space’s high, two-story bay presenting like an awkward setup for laboratory work, the height proved to be the perfect site to practice mockups of the arms and fabrics and foils unfolding. Taking the time to match Professor Pellegrino’s proposed research needs with the space’s possibilities allowed MATT’s team to build a space that perfectly suited the work.

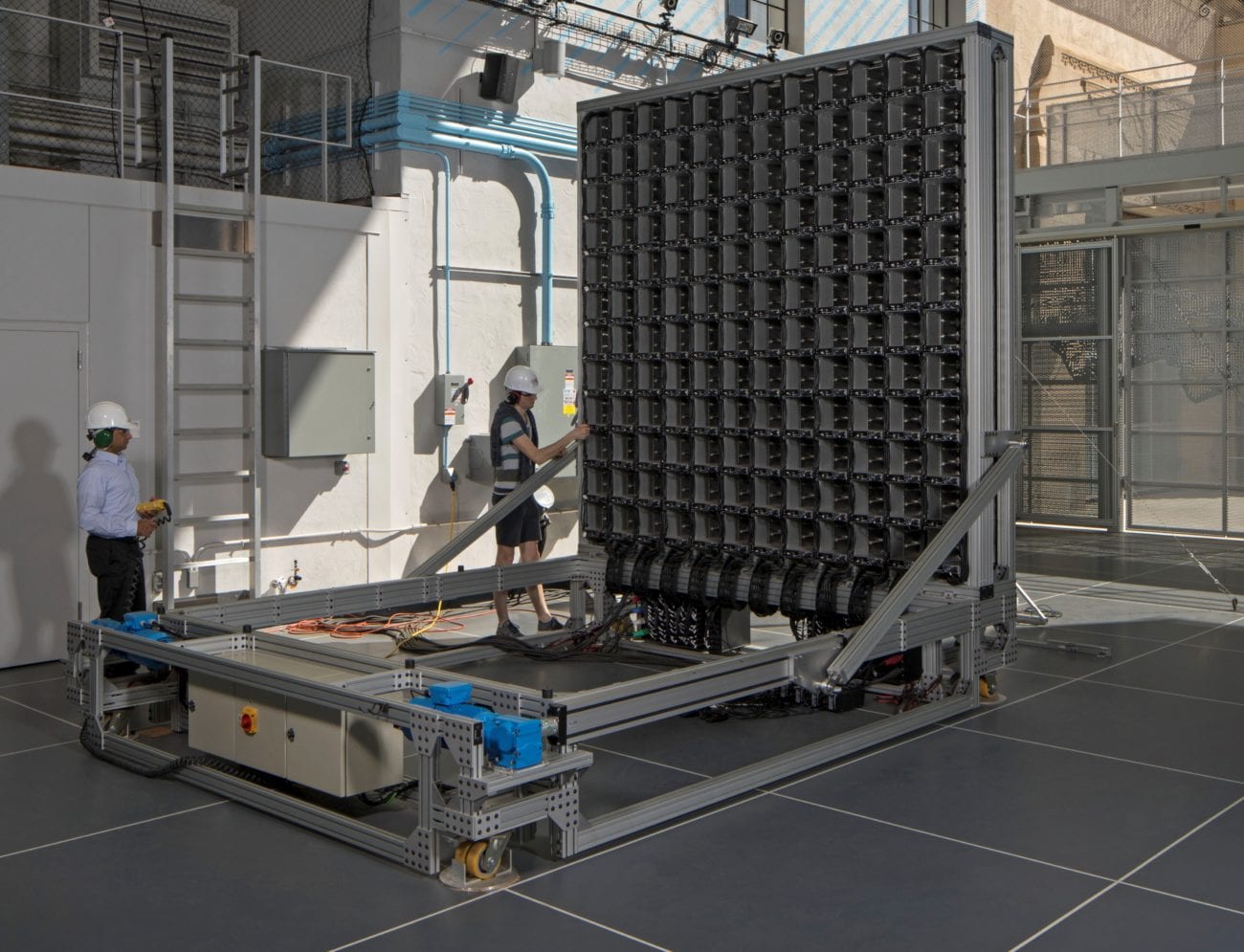

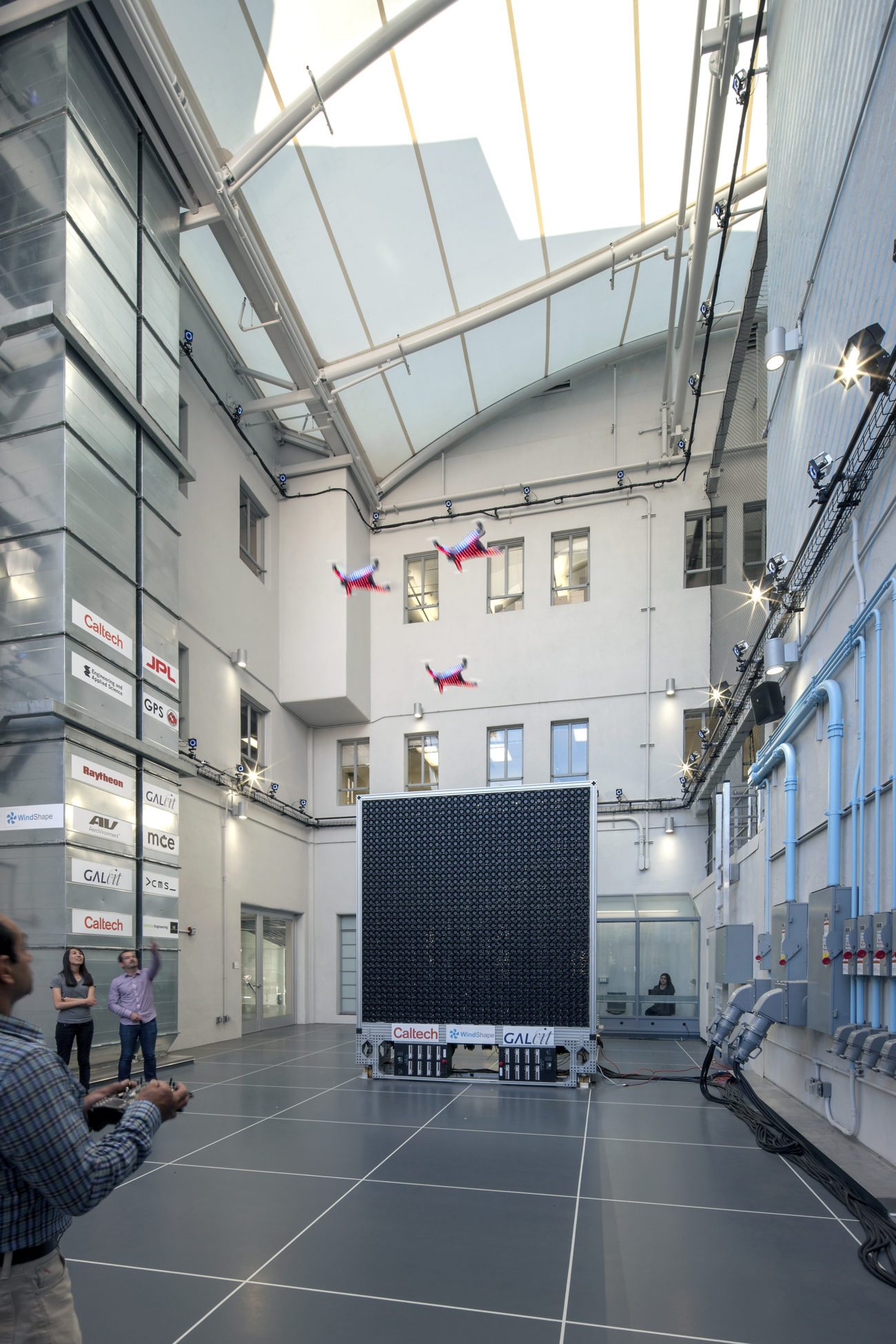

Building the first-of-its-kind, two-ton, 10’ x 10’ fan wall that generates conditions similar to all manner of extreme weather conditions for drone test flights in the CAST Lab’s exterior Aerodrome arena put the team to the test. It was being designed and conceived by Caltech simultaneous to the development of the CAST design and the actual building of SSPI. Researchers wanted the device’s 1,296 CPU fans to be individually controllable and operate on a motorized tilt array, generating gusts, windshear, sandstorms and additional hazards. To simulate air flow patterns, the design team used computational fluid dynamic and acoustical modeling. The question of how to anchor the massive wall’s proposed concrete slab led to a realization that a fixed apparatus came with greater limitations than something mobile. This insight prompted the end-user team to opt for a moving wall rather than a fixed apparatus. This helped the construction team by obviating the need to go back and add more support beams under the floor to accommodate an anchored system. Instead, they loaded the design specs onto existing lab criteria and spread the load. Researchers also weighed in early on with the request to have their robotic Assembly Lab located close to the Aerodrome arena for testing. The nearby observation deck allows scientists, companies and investors from around the world to witness live demonstrations of the fan wall’s abilities potentially partner with Caltech in the future.

According to Labov, the Aerodrome’s rooftop canopy “couldn’t have been done in a way that made sense if we didn’t have the contractor on board early.” Caltech wanted a well-lit, waterproof outdoor testing arena with controlled airflow. Keeping the rain out while letting the natural light and a measured amount of air in presented a huge challenge. MATT worked with a fabricator to navigate the tall, narrow space and its limited access, building an entire loading dock just to assemble the components. They had to select and drive a boom lift, drop it onto the newly constructed loading dock, then do the work from there, “a lot of gymnastics and choreography,” as Labov puts it. The canopy itself, which spans over a few thousand square feet, called for a design-assist contractor from Texas who normally crafts stadium covers. He had already worked with MATT at the Natural History Museum, making for a smooth, joint problem-solving dynamic. The team ran through numerous iterations of different roofing systems and materials before finalizing on a tensile fabric that met the budget and physical constraints of the space. The translucent material transmits diffuse daylight, reducing lighting loads. It also helps to absorb the sound that bounces off the courtyard’s walls when the fan wall is in operation. The architectural uniqueness of the design element garnered widespread interest in and further funding for the project.

Staying on Budget with Evolving Design

Throughout projects like the SSPI and CAST Labs, and particularly during the design phase, MATT weighs in on scope and stays on top of the budget and pricing. Having a solid roadmap for critical construction stages helps the team at large with communication and timeliness, minimizing the potential for delays. MATT’s weekly OAC meetings facilitate this fluid dialogue. They use these opportunities to make sure everyone involved understands scheduling and sequencing, especially related to procurement. In a design-build scenario, Labov comments, “you can’t just go and buy something out of a catalogue.” You have to develop mockups and build trust with the end-users, demonstrating that you can deliver on what they envision while managing the risk that goes along with design-build. There’s a great satisfaction that comes from “doing something innovative and doing it in a way that’s affordable.”

Labov feels design-build is a much better option for staying on budget, because you have direct access to the market and can get a faster reaction to cost. Trying to manage expectations sometimes requires rebalancing the budget; if something costs more in one area, the team may have to consult alternative suppliers and reduce the cost of an item to put money back into another element. Having MATT on board during this process, weighing in on real costs, supplier options and other feasibility issues, helped to keep the budget in check. In the CAST Lab lobby, for example, the design called for a free-flowing set of panels that drape downwards to evoke airflow. Their original wooden egg crate conception came in over budget, so MATT’s team proposed a subcontractor who could custom-build a metal alternative that would capture the spirit of the original intent but save on cost.

Making Space Flexible for the Future

As technology continues to fuel science and vice-versa, flexibility is paramount but tricky to implement. Due to the rapidly shifting landscape of laboratory equipment and unpredictable advances in various fields, it pays to be adaptable during the design process. That means learning what’s flexible and what isn’t. Contractors play a central role in these feasibility reviews. Their input guides the team’s collective decisions around how best to serve current needs while bearing in mind that the space itself may someday be repurposed for an entirely different research agenda.

“What I learned from SSPI in particular is that we change the way we think about certain kinds of labs. We used to think of labs as wet labs and dry labs,” Labov reflects. But at Caltech, they encountered a new type of lab: the spec lab, “designed around a very specific performance criterion or apparatus. In order to do that in the lab effectively and make it flexible,” the team had to be especially creative while also working with the building’s existing constraints. A high-volume space such as the 22-foot bay running upwards from the Karman basement, for example, could be parceled out into three different areas, allowing for a balcony or mezzanine with stacked offices while finding space for a clean room and air handling unit, all of which could be repurposed by future researchers with different agendas.

CO and MATT enjoy the rewards of collaborating with innovative thinkers in the scientific community and have outfitted a number of recent design-build laboratory spaces at Caltech, including the Oka and Hong renovation, the Shapiro Lab and the Faber Lab. What sets the stage for these successful construction partnerships is the team’s collective ability to build interdisciplinary bridges of understanding and adapt to the unforeseeable challenges and surprising opportunities that go hand-in-hand with exploration.