Location

Woodland Hills, CA

Owner

Terasaki Institute for Biomedical Innovation (TIBI)

Architect

CO Architects

Project Size

50,000 SF

ViewTop 4 Things to Know When Building Your Life Science Facility

Creating your life science space with functionality, innovation, and success at the forefront

The life sciences industry has experienced significant growth in the past few years and has seen record high employment driven by biotechnology and industry innovation. As this industry continues to make strides with no signs of slowing, the demand for facilities continues to grow alongside it. Newly budding real estate developers and owners are capitalizing on this demand and have shifted focus from traditional office spaces and are now putting emphasis on the life sciences sector. However, shaping the life science built environment is no walk in the park; there are many important considerations that must be accounted for to guarantee a life science space is functional for tenants and built for success.

1. Vibration Criteria

When building a life science facility, it is crucial to understand the vibration criteria for different types of research and development. Unlike a standard building, such as a multi-family home whose structure can maintain a higher vibrational level, a wet lab facility must sustain a level of stability for safety purposes and specific lab requirements. If certain vibration levels are not maintained, an experiment’s results may be compromised or even unusable. While there are options to provide point-of-use vibrational stability such as damping pads, designing a building to a specific criterion gives the tenant more flexibility in the type of research they can conduct within the facility and increases demand for space.

One of MATT’s current clients is adapting a retired magazine headquarters into a life science facility. The existing structure is well-located and meets the desired square footage; however, once the MATT team began demolition, they recognized that the existing structure did not meet the vibration criteria for the future lab space. The MATT and design team quickly conjured up numerous scenarios to fine-tune the design to meet the desired vibration criteria. The final solution was to build a structure within the skeleton of the building to support the main building structure, a sort of “building within a building”. While this impacted other trades, MATT’s creative solution not only allowed tenant flexibility in their life science lab, but also led to a cost-effective solution with minimal schedule impacts and a functional lab space.

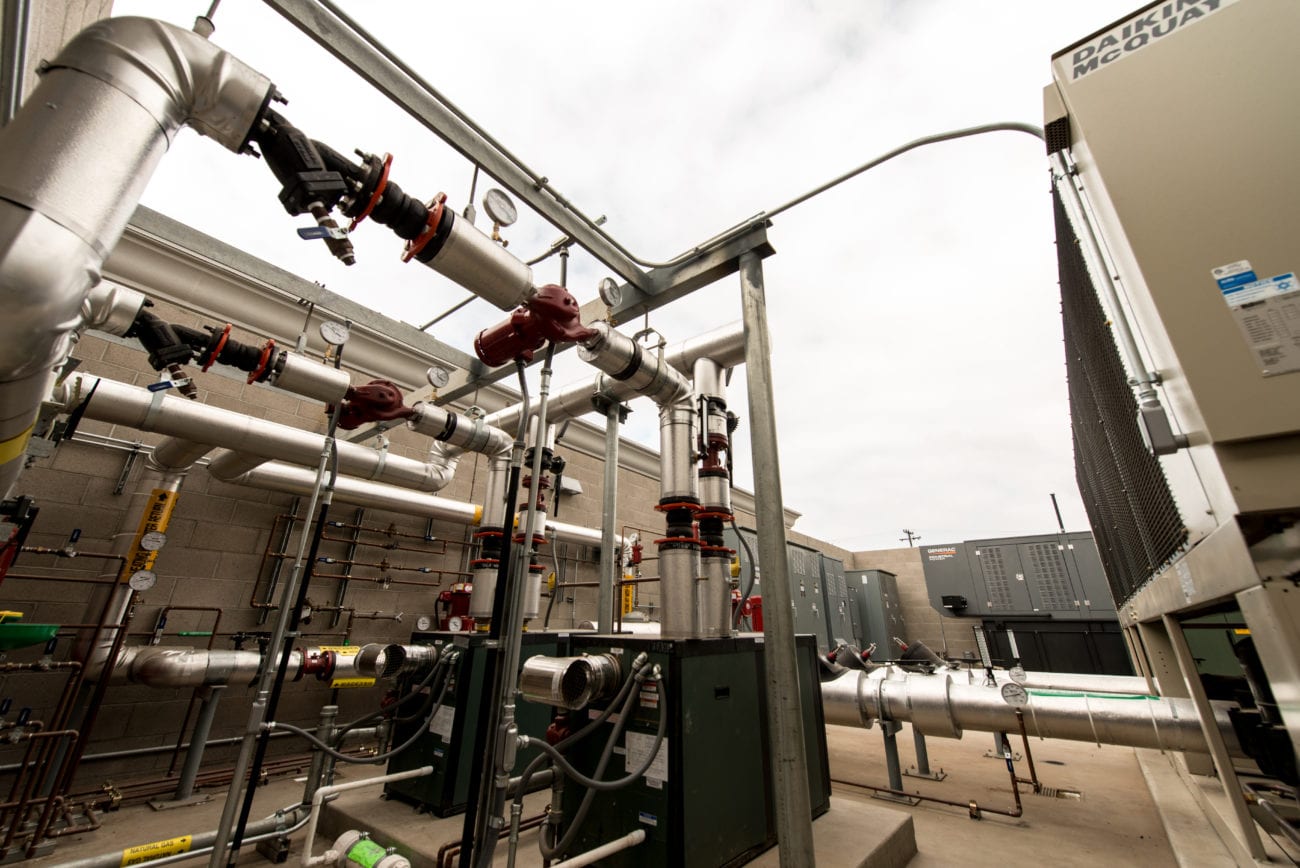

2. Cost-Effective Mechanical Separation

Life science buildings often have specialized infrastructure that requires extremely complex mechanical systems. It is common practice for specific equipment in a lab space to have individualized mechanical systems; for example, a virology lab requires biological safety cabinets with their own mechanical system separate from the rest of the lab to keep scientists safe from coming in close contact with pathogens. While a design team can develop parameters for this system, a general contractor is an asset in developing a cost-effective approach for mechanical separation. Focusing on these details upfront allows for efficient design with cost and schedule certainty and eliminates the possibility of having to rework the design later in the project.

Typically, a building’s mechanical systems sit on the roof. However, at the same facility mentioned above, the pre-existing roof was unable to support the additional load of the increased mechanical systems required by the lab. The MATT and design team again was able to adapt, composing the novel idea to fabricate a mechanical well through the building, with watertight waterproofing and all, to accommodate the exhaust fan equpiment and ductwork. The exhaust ended up sitting 15ft above the roof in order to properly diffuse air.

3. Workflow

The key to a successful life science facility is efficiency. Workflow optimization is integral to making a process as advanced, efficient and lean as possible. Focusing on functionality is key. Supplies should be nearby and accessible, the sequence of procedures should determine the layout of a space, and movement should be minimized as much as practicable. Just as a scientist would arrange an experiment to maximize their time, the space itself needs to be optimized too. Workflow doesn’t just begin at the granular level; it should be integrated into the beginning steps of designing a life science space. Being intentional by organizing the space with a realistic workflow in mind maximizes the potential of the space for the tenant.

While speaking with the scientists at one of MATT’s life science projects, the team realized that there was no efficient method for transferring samples, and the current plan did not allow for effective flow of materials. The MATT team suggested adding an elevator with openings on both sides, allowing access to both the wet lab zone and the work documentation area to ensure sensitive samples didn’t need to be exposed to the entire facility during transportation. Although not initially included in the project’s design plans, this adjustment was a key asset to the lab’s workflow efficiency and safety measures.

4. Thinking Beyond the Lab Space

Innovation rarely happens without collaboration, and most life science spaces require more than just a wet lab or research facility to pave the way. Scientists use creativity to determine what types of questions yield results, to dream up possible answers to their questions, and to imagine ways to expertly answer those questions. Creating a space to promote this type of thinking is essential to answering some of life’s greatest questions. MATT, unlike many developers and contractors, brings first-rate expertise to this essential part of constructing a life science space, having built many creative offices like Google Spruce Goose, Chiat Day, Conrad Hilton Foundation Headquarters and Annenberg Sunnylands. These unique spaces are the gold standard in promoting divergent thinking and accelerating collaboration and can be used as inspiration when building facilities that surpass the capabilities of a standard lab space.

MATT anticipates continued growth in the demand for innovative life science spaces that continue to break the mold and lead to revolutionary discoveries. To capitalize on this opportunity, developers and owners should prioritize these four key elements when aiming to effectively serve the life science market and build for success.